Why do microwave magnetron outputs have holes if they're not waveguides?

2019-10-26 #1

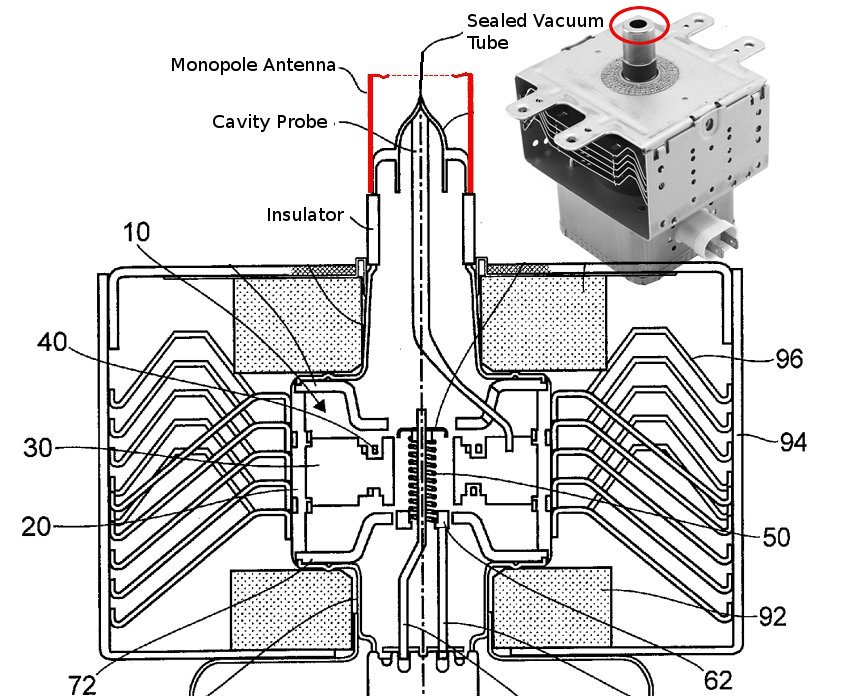

I've been looking at a lot of microwave oven magnetrons lately. One thing that vexed me was why they all seem to have a hole in the cap on their output. Initially this predisposes you to think that it's an aperture of a waveguide. But the wavelength of of 2.4 GHz in air is way to large for the size of the 'waveguide'. For a 'waveguide' that small it'd only support about 15 GHz wavelength as the lowest frequency and support up to some ~20 GHz before high end cut-off.

It's actually a monopole antenna with a dielectric standoff. The fatter the monopole the greater the bandwidth generally, and the larger the better heat tolerance, and the lower the e-field gradients. So it makes sense to use a fat cylinder for the monopole. But what doesn't make sense is that there's a hole in the end of it. In all of them.

After reading a few patents I think I know why. Originally the vacuum evacuation tube comes out of the top of the magnetron. It's normally closed off but it's still under the antenna cap. If the antenna has a hole in it then the magnetron can be tested somewhat normally while still being hooked up to the vacuum pump. That's my guess. I can't think of any other reason for it beyond letting hot air out of the cavity beneath the antenna.

I ended up emailing a number of people who seemed to be authorities or at least very knowledgable on commercial oven magnetron operation. The consensus of *all* of them was that the hole in the cap really didn't matter and it was just there to cover the sharp edges of the sealed evacuation tube. But few really seemed to know why they all have little holes on the end. Until today (a week since I started digging) when two people confirmed that the holes *are* just for mechanical assembly.

There is no electrical reason for the hole: the antenna with such a hole behaves exactly the same way as without a hole. The cap serves for defining/unifying the magnetron radiating structure shape and protection from the sharp edges of the sealed evacuation tube end.

I am not a magnetron technology specialist but the hole must have some prosaic technological reason, such as air vent when the cap is pressed onto the magnetron. In mass production, this may be a very snappy operation.

Magnetrons are certainly not tested in any electric way while being hooked up to the vacuum pump. A "magnetron" is then just a bare bulb without electric connections, without magnets, without the cap alone.

- Vladimir Bilik

<_abc_> The hole in the top of tha probe on an oven magnetron serves as assembly help. There's an equivalent hole on almost all anode contact caps on tubes, sometimes it is smaller and soldered closed. http://danyk.cz/gu81_en.html Different style, same idea, the little tab is spot welded to the wire coming out of the glas